Toyota’s Evolution: A Journey Through Automotive History

2025 Aug 01

Toyota Motor Corporation stands as one of the world’s most influential automotive manufacturers, with a rich history spanning over eight decades. From its humble beginnings as a textile machinery company to becoming a global leader in automotive innovation, Toyota’s evolution reflects the broader transformation of the automotive industry itself. This article explores four pivotal aspects of Toyota’s remarkable journey.

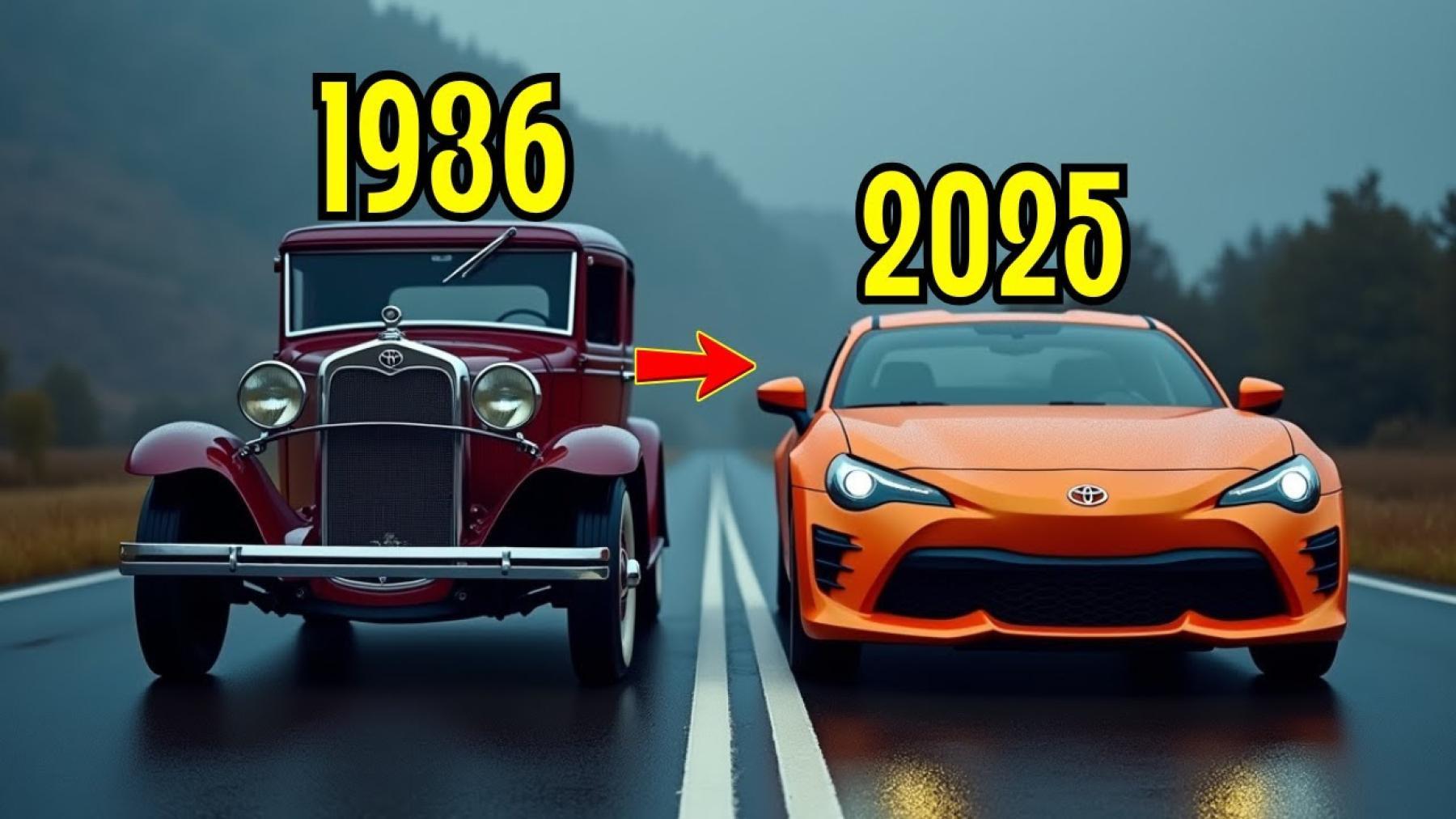

1. From Textiles to Automobiles: The Foundation Years (1930s-1950s)

Toyota’s automotive story begins in an unexpected place, the textile industry. In 1918, Sakichi Toyoda founded Toyoda Automatic Loom Works, which became highly successful in manufacturing textile machinery. However, it was his son, Kiichiro Toyoda, who would pivot the family business toward automobiles.

In 1933, Kiichiro established an automobile department within the loom company, driven by his vision that Japan needed its own automotive industry. The company’s first passenger car, the Model AA, rolled off the production line in 1936. This marked the beginning of what would become Toyota Motor Co., Ltd., officially established in 1937.

The early years were challenging, with World War II disrupting production and forcing the company to manufacture trucks for the military. However, these difficulties taught Toyota valuable lessons about efficiency and resource optimization that would later become fundamental to their philosophy. By the 1950s, Toyota had resumed civilian vehicle production and began developing the quality control and manufacturing principles that would define their future success.

The foundation years established Toyota’s core values of continuous improvement (kaizen), respect for people, and long-term thinking. These principles, rooted in Japanese culture and refined through necessity, would become the bedrock of Toyota’s eventual global dominance.

2. The Toyota Production System: Revolutionizing Manufacturing

Perhaps no single contribution has been more influential to the automotive industry than the Toyota Production System (TPS), developed primarily in the 1950s and 1960s under the guidance of Taiichi Ohno and other Toyota engineers. This revolutionary approach to manufacturing fundamentally changed how cars are made worldwide.

The TPS introduced several groundbreaking concepts that seemed counterintuitive at the time. The “Just-in-Time” production method eliminated waste by producing only what was needed, when it was needed, and in the exact quantity required. This approach drastically reduced inventory costs and improved quality control by making defects immediately visible.

Another cornerstone of TPS was “jidoka,” or automation with a human touch. This principle empowered workers to stop the production line whenever they detected a problem, ensuring that defects were addressed immediately rather than passed down the line. This approach fostered a culture of quality and continuous improvement that became synonymous with Toyota vehicles.

The kanban system, using visual cards to signal production needs, streamlined communication and coordination across the manufacturing process. These innovations collectively created a lean manufacturing approach that maximized efficiency while minimizing waste.

The impact of TPS extended far beyond Toyota’s factories. Companies across industries worldwide adopted lean manufacturing principles, making Toyota’s production philosophy one of the most studied and emulated business practices in modern history. The system’s emphasis on employee engagement, continuous improvement, and quality excellence became a model for operational excellence globally.

3. Global Expansion and Market Leadership (1960s-2000s)

Toyota’s transformation from a domestic Japanese manufacturer to a global automotive powerhouse began in earnest during the 1960s. The company’s international expansion strategy was methodical and well-planned, reflecting their long-term business philosophy.

The journey started with exports to Southeast Asia and South America in the early 1960s, followed by entry into the crucial American market in 1965 with the compact Corona model. Initially, Toyota faced skepticism from American consumers who associated Japanese products with poor quality. However, the 1973 oil crisis proved to be a turning point, as consumers suddenly prioritized fuel efficiency over size and power areas where Toyota excelled.

Throughout the 1970s and 1980s, Toyota steadily gained market share by focusing on reliability, fuel efficiency, and value. Models like the Corolla and Camry became household names, consistently ranking among the best-selling vehicles in their respective categories. The Corolla, in particular, became the world’s best-selling car model, with over 50 million units sold since its introduction in 1966.

Toyota’s expansion strategy included establishing manufacturing plants in key markets rather than relying solely on exports. The first overseas manufacturing facility opened in Brazil in 1959, followed by plants in the United States, Europe, and other regions. This localization strategy helped Toyota avoid trade barriers, reduce costs, and better serve local market preferences.

By the 1990s, Toyota had become one of the world’s largest automakers, consistently competing with General Motors and Volkswagen for the top position in global vehicle sales. The company’s reputation for quality and reliability became so strong that “Toyota reliability” became a common phrase, and their vehicles consistently topped customer satisfaction and quality surveys.

4. Innovation Leadership: Hybrid Technology and Environmental Stewardship

The late 20th and early 21st centuries marked Toyota’s emergence as a leader in automotive innovation, particularly in environmental technology. This period demonstrated the company’s ability to anticipate market trends and invest heavily in future technologies, even when their commercial viability was uncertain.

The most significant breakthrough came in 1997 with the launch of the Toyota Prius, the world’s first mass-produced hybrid vehicle. The Prius represented a bold bet on environmental consciousness and fuel efficiency at a time when gas prices were relatively low and environmental concerns were not yet mainstream consumer priorities.

The development of hybrid technology required Toyota to master complex systems integration, combining gasoline engines with electric motors, sophisticated battery systems, and advanced control electronics. This technological achievement positioned Toyota as the undisputed leader in hybrid technology, with over 15 million hybrid vehicles sold worldwide by 2020.

Toyota’s commitment to environmental stewardship extended beyond hybrid technology. The company set ambitious goals for reducing manufacturing emissions, implemented comprehensive recycling programs, and invested heavily in research for hydrogen fuel cell technology. The introduction of the Mirai fuel cell vehicle in 2014 demonstrated Toyota’s continued commitment to zero-emission transportation solutions.

In recent years, Toyota has expanded their electrification strategy to include plug-in hybrids, battery electric vehicles, and fuel cell vehicles. The company’s approach reflects their philosophy of offering multiple pathways to sustainable mobility, recognizing that different regions and use cases may require different solutions.

Beyond environmental technology, Toyota has remained at the forefront of safety innovation with the Toyota Safety Sense suite of driver assistance technologies, and has invested heavily in autonomous driving research and connected vehicle technologies. These innovations continue Toyota’s tradition of anticipating future needs and developing practical solutions.

Conclusion

Toyota’s evolution from a textile machinery company to a global automotive leader illustrates the power of continuous improvement, long-term thinking, and adaptability. The company’s journey demonstrates how fundamental business principles-quality, efficiency, respect for people, and environmental responsibility-can create lasting competitive advantages.

Today, as the automotive industry faces unprecedented change with electrification, autonomous driving, and new mobility services, Toyota’s history suggests they are well-positioned to continue evolving. Their experience in managing technological transitions, combined with their strong operational foundation and global presence, provides a solid platform for navigating the challenges and opportunities ahead.

The Toyota story is ultimately one of transformation and adaptation, showing how a company can maintain its core values while continuously evolving to meet changing market demands. As the automotive industry enters a new era of innovation and sustainability, Toyota’s legacy of thoughtful evolution and technological leadership continues to influence the direction of transportation worldwide.